We leverage proven processes, advanced technology and ongoing communication to deliver exceptional service and ensure smooth-running food service programs.

Our Processes

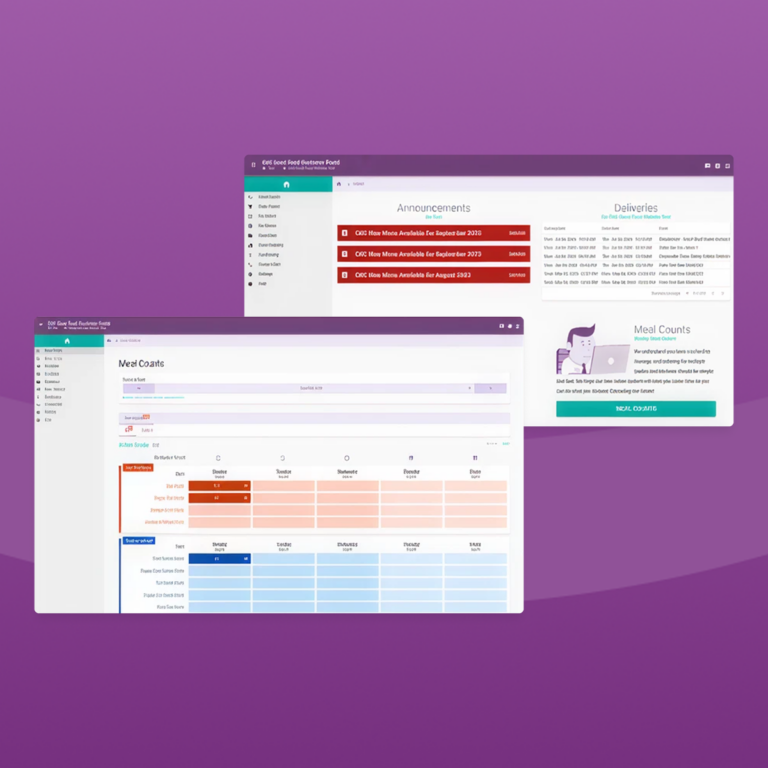

Intuitive Client Portal Makes Ordering Easy

Every CKC Good Food client has access to our custom-designed, easy-to-use client portal, which is the hub for your food service program’s daily operations.

Your Client Services Manager will walk you through the portal, explaining how to submit and change meal orders, download and print food production records and nutritional data, access helpful resources and place orders for non-meal items like paper products.

Client Services Team Keeps Operations Humming

CKC Good Food believes the continuous support we provide to every client partner is as important as the quality of our meals.

Each client partner is paired with a dedicated Client Services Manager who visits your site/s regularly to observe your food service operations and provide ongoing training. They assess service flow, adherence to proper procedures and HACCP compliance; answer questions; address any challenges; and communicate any updates or procedural changes, whether a change required by government regulations or CKC Good Food. This hands-on, consistent support is key to your daily success and compliance with procedures and, if applicable, USDA guidelines.

Warehouse and Inventory Management Processes Minimize Shortages

Our 42,000 square foot facility in Eagan, where we began operating in 2022, has a a large warehouse complete with cold storage and seven dock doors.

The expanded capacity and improved logistics have allowed us to elevate the quality, quantity and consistency of inventory on hand to expand our production capacity. Our inventory management processes have built-in redundancy to stay ahead of shortages and minimize substitutions in our menus.

Tagger System Ensures Complete Meal Deliveries

On a typical day, CKC Good Food’s main kitchen produces more than 28,000 meals from multiple iterations of recipes. It’s a logistical wonder to get the right meals in the proper quantities into the right vans to be delivered to the right locations.

Our proprietary tagger system accounts for every component of every meal, from inventory through delivery. A few days before to a meal being served, tags are generated for each client site based on the day’s menu and quantity needed. The day before service, our prep team readies the meals, placing a tag on each pan of hot food, bag of cold sides and box of bulk dry goods for every serving site. After meals are heated the next day, our drivers go through their checklists for deliveries, counting each pan, bag and box to ensure everything needed for the day’s meals is loaded and delivered.

Let’s Work Together

Interested in having CKC Good Food submit a proposal for your food service program? Have questions and want to talk to our team?